00

:

00

:

00

Get Flat 5% Discount

Get Flat 5% Discount on All Packaging Products For New Customers

Next Day Delivery

on All Orders

Volume Discounts

when buying in bulk

Key Accounts

Credit Terms & Trade Prices

Get Flat 5% Discount

Get Flat 5% Discount on All Packaging Products For New Customers

on All Orders

when buying in bulk

Credit Terms & Trade Prices

Your warehouse is the heart of your supply chain. Standardizing label formats with GS1 best practices ensures every item moves smoothly, reducing errors and boosting efficiency. This guide shows you how to implement GS1 standards step by step, making your operations seamless and compliant.

GS1 standards create a universal language for supply chains. Over 1.5 million companies in 152 countries use them, covering 80% of global retail trade (GS1 Standards). They ensure your labels are consistent, traceable, and globally recognized.

Standardized labels prevent costly mistakes. Misidentified shipments can delay deliveries or disrupt inventory. GS1’s framework minimizes these risks, connecting you with retailers, manufacturers, and logistics providers.

GS1 is a global non-profit that develops standards for barcodes, RFID, and data sharing. Its systems identify products, shipments, and locations uniquely. In warehouses, GS1 standards streamline inventory tracking and logistics.

These standards are not just technical rules. They enable real-time data sharing across supply chains. Your warehouse becomes a hub of accurate, reliable information.

GS1 logistic labels are designed for clarity. They consist of three blocks:

Each block serves a purpose, ensuring both machines and people can process the information.

These components make labels versatile and reliable. They support automated scanning and manual checks. Your warehouse stays efficient and error-free.

Creating GS1-compliant labels requires precision. Follow these steps to get it right:

Every logistic unit needs a unique SSCC. Use your GS1 Company Prefix to create it. This ensures each shipment is traceable across the supply chain.

GS1 offers two standard sizes: A6 (105 mm x 148 mm) for compact labels and A5 (148 mm x 210 mm) for more data. Pick based on your information needs. Smaller labels save space; larger ones accommodate extra details.

Adhere to GS1 guidelines for barcode dimensions, quiet zones, and check digits. The GS1 Logistic Label Guideline details these requirements. Non-compliant labels risk scanning failures and delays.

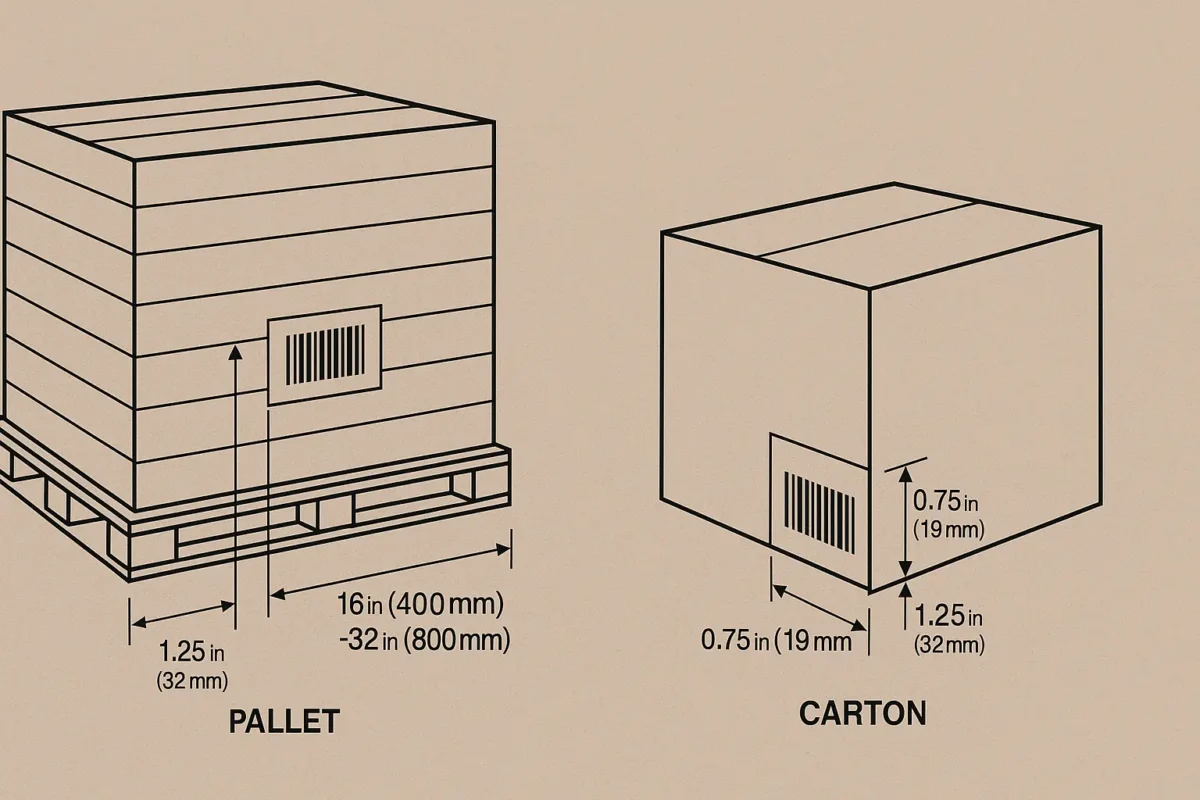

Correct label placement ensures efficient scanning. Misplaced labels slow down operations. Follow these guidelines:

These rules ensure scanners can read labels easily. Proper placement reduces errors during receiving and shipping.

Scan the SSCC upon receipt to match it with the Advance Ship Notice (ASN). This confirms the shipment matches what was sent. Update your inventory system to keep records accurate.

GS1 standards integrate with warehouse technology for maximum efficiency. They streamline processes and reduce manual work. Here’s how to implement them:

Barcodes and scanners enable fast, accurate inventory tracking. AIDC eliminates manual data entry, cutting errors. Your warehouse processes become quicker and more reliable.

Link GS1 labels to your WMS for real-time stock updates. This integration tracks item locations and movements instantly. It simplifies inventory management and decision-making.

Use SSCC and ASN for efficient cross-docking. Goods move directly from incoming to outgoing transport, reducing storage time. This speeds up deliveries and cuts costs.

Clear roles ensure GS1 standards work smoothly. Both shippers and receivers have specific tasks. Missteps here can disrupt the supply chain.

These practices keep your supply chain running smoothly. Everyone plays a role in maintaining traceability.

GS1 standardization transforms your warehouse operations. It offers clear, measurable advantages. Here are the key benefits:

These benefits save time, money, and headaches. Your warehouse becomes a well-oiled machine.

Real-world examples show GS1 standardization in action. These cases highlight tangible results. They prove the value of adopting these practices.

A major retail chain adopted GS1 labels across its warehouses. Inventory discrepancies dropped by 30%, saving $2 million annually. Processing speed increased by 20%, handling 500 more shipments daily.

A manufacturer implemented GS1 labeling for its shipments. On-time deliveries improved from 85% to 95%. Customer satisfaction scores rose by 15 points on a 100-point scale.

These successes show what’s possible with GS1 standards. Your warehouse can achieve similar results.

Implementing GS1 standards isn’t foolproof. Small mistakes can cause big problems. Avoid these common pitfalls:

These errors can disrupt operations. Proper training and adherence to guidelines prevent them.

GS1 labels offer advanced options for specific needs. These features can enhance your operations. Consider these additions:

These features are less common but valuable in complex supply chains. Evaluate if they suit your needs.

Standardization isn’t always smooth. Resistance to change and system integration can pose challenges. Address these proactively:

Planning and communication overcome these hurdles. Your warehouse will adapt quickly.

Start small and scale up. Pilot GS1 labels on one product line before full implementation. Monitor results and adjust as needed.

Invest in quality printers and scanners. They ensure labels are clear and scannable. Poor equipment can undermine your efforts.

Regularly audit your labeling process. Check for compliance and accuracy monthly. This keeps your system reliable.

GS1 standards are widely adopted in retail, manufacturing, and logistics. Over 80% of global retail trade relies on them (GS1 Standards). This widespread use ensures compatibility with partners worldwide.

Retailers like Walmart and Amazon mandate GS1 compliance for suppliers. Manufacturers benefit from faster order fulfillment. Logistics providers streamline cross-docking with GS1 labels.

GS1 standards evolve with technology. RFID and IoT integration are growing trends. These advancements will further improve traceability and efficiency.

Stay updated with GS1’s latest guidelines. Regular training keeps your team prepared. Your warehouse will stay ahead of the curve.

1. What are the key benefits of standardising warehouse label formats using GS1?

Standardisation improves accuracy, speeds up scanning, enhances traceability, and ensures global compliance.

2. How do GS1 standards improve warehouse labeling accuracy?

They define consistent data formats and barcode symbologies, reducing errors and misreads.

3. What is a Serial Shipping Container Code (SSCC) and why is it important?

SSCC is a unique 18-digit code identifying logistic units, enabling precise tracking.

4. How should GS1-128 barcodes be formatted for warehouse labels?

They must include Application Identifiers, have minimum size and quiet zones, and meet print quality standards.

5. What are Application Identifiers (AIs) in GS1 labeling?

AIs are prefixes that specify the type and format of data encoded in barcodes.

6. How does Human Readable Interpretation (HRI) help in warehouse operations?

HRI displays barcode data as text for manual verification and error checking.

7. Where should pallet labels be placed according to GS1 guidelines?

On the side of the pallet facing conveyors or forklift operators for easy scanning.

8. What materials are recommended for durable GS1 logistic labels?

Polyester or synthetic substrates with strong adhesives resistant to moisture and abrasion.

9. How does standardising label formats enhance supply chain traceability?

It enables consistent data capture at each stage, improving visibility and recall management.

10. What are common mistakes to avoid when implementing GS1 label standards?

Ignoring size requirements, poor print quality, incorrect AI usage, and improper label placement.

11. How can warehouses ensure compliance with GS1 label guidelines?

By following GS1 manuals, conducting regular audits, and using label verification tools.

12. What is the difference between GS1-128 and GS1 DataMatrix barcodes?

GS1-128 is a linear barcode; DataMatrix is a 2D code that holds more data in less space.

13. How do GS1 labels integrate with Warehouse Management Systems (WMS)?

WMS reads barcode data to update inventory and automate workflows like shipping and receiving.

14. What is the minimum size requirement for GS1 barcodes on logistic labels?

Barcodes must be at least 32mm in height with proper quiet zones on each side.

15. How often should barcode print quality be verified in warehouses?

Regularly, ideally before production runs and periodically during operations.

16. What information must be included on a GS1 logistic label?

SSCC, GTIN, batch/lot numbers, expiration dates, and handling instructions as needed.

17. How do GS1 labels support automated receiving and cross-docking?

By providing machine-readable data that triggers system actions without manual input.

18. Can GS1 logistic labels include batch numbers and expiration dates?

Yes, using specific Application Identifiers for each data element.

19. What are quiet zones in barcode labeling and why are they important?

Blank spaces around barcodes that prevent scanning errors by separating the code from other elements.

20. How do GS1 standards help reduce shipping errors and delays?

They ensure consistent, accurate labeling that systems and workers can trust, minimizing mistakes.